In recent years, UV-LED curing technology has received worldwide attention, and in many applications, UV-LED light sources have been gradually replaced by conventional mercury light sources. UV-LED is an electroluminescent diode that is more environmentally friendly, efficient and has lower energy consumption than traditional UV mercury lamps. It is a truly green industrial technology for sustainable development.

UV-LED features:

1.Single wavelength, high luminous efficiency and low energy consumption.

UV-LED can directly convert electrical energy into UV light, and emits single-band ultraviolet light. The light energy is highly concentrated in a specific ultraviolet light band. Currently, there are mature applications in the market: 365nm, 385nm, 395nm, 405nm. . The emission spectrum of the traditional UV mercury lamp is very wide, and the ultraviolet spectrum segment which actually plays an effective curing role only accounts for a part of it, and the photoelectric conversion efficiency is low, and the energy consumption is large.

2.Does not produce infrared and ozone.

Conventional mercury lamps generate infrared light and emit a large amount of heat, which is easy to damage heat sensitive substrates. The UV-LED is a cold light source, which can effectively prevent the substrate from shrinking and deforming due to overheating, and has wider adaptability to materials. At the same time, the UV-LED used for UV curing is usually a long-wavelength ultraviolet light, so ozone is not generated during the curing process, and a good working environment can be maintained, which is safer and more environmentally friendly than conventional mercury lamps.

3.Point and light, electronic control.

The UV-LED does not need to be preheated like a mercury lamp, nor does it need to keep the lamp normally open in order to maintain lamp life and work efficiency. UV-LED can instantly turn on (off) the light, the output energy can also be set freely, and can be automatically adjusted by the speed of the random machine. It is very energy-saving and easy to control.

4.Long service life and low maintenance costs.

The service life of UV-LED lamps can reach 10,000-50,000 hours or more, which is more than 10 times that of traditional mercury lamps, and the light attenuation is very slow, and the service life is not affected by the number of switches. At the same time, the LED light source has no mercury and no accessories such as a lampshade, so almost no maintenance is required, and maintenance costs are reduced.

5.High flexibility for use and small system size.

The UV-LED source can be divided into a point source, a line source, and a surface source, and the effective illumination area can be customized. The size of the light source equipment is small, the illumination device and related equipment are very compact, and there is no need for the large mechanical installation space and pipeline construction in the past. This feature makes it adaptable to all types of production processes and the production process is more efficient.

Comparison of sales of UV-LED and traditional UV mercury lamp equipment from 2011 to 2016

UV-LED market:

According to TechNavio, the UV-LED market has maintained very high growth rates in the last seven or eight years, from $20 million in 2008 to $90 million in 2014, with a compound annual growth rate of 28.5%. In 2016, due to the active introduction of UV LED products into various applications such as photocuring, sterilization and purification markets, the estimated output value will reach US$166 million, of which LEDs will be used in the photocuring market with an output value of US$81 million. By 2020, the global average annual growth rate of the UV-LED technology market will reach 39%.

In 2015, the UV curing market accounted for 48.14% of the UV-LED technology market. The demand for UV-LED curing equipment in the printing industry has increased, and the flux density for UV-LED chips has been greatly improved. UV curing has occupied a large part of the UV-LED technology market, and the printing industry has developed into a UV-LED curing device. A big user. UV-LED technology has achieved great success in the inkjet field, driving the application of UV-LED technology throughout the printing industry.

UV-LED technology in Asian markets:

European UV-LED technology will grow from $36.28 million in 2015 to $190.2 million in 2020. Environmental regulation of hazardous substances in Europe and bans on mercury lamps have made the European market an important contributor to the global UV-LED market. Since UV-LEDs are environmentally friendly and consume less power, they have a large number of applications in the medical, adhesive, and printing curing markets in Europe, and these applications have also become an important factor in the growth of the European market.

UV-LED technology in the North American market:

UV-LED technology accounts for 26.8% of the North American market. TechNavio predicts that the North American UV-LED technology market will grow from $34.33 million in 2015 to $179.06 million in 2020. Due to the rapid growth of the market, the flat art industry in North America is increasingly using UV curing equipment and technology. Other UV-LED light curing applications involve the healthcare industry, the communications equipment industry, the automotive industry, and the building materials industry.

UV-LED application field:

Since the UV-LED is a single-band UV light source, the absorption spectrum of the initiator needs to match the emission spectrum of the LED. At present, there are not many initiators developed for the LED light source on the market, and the mass production is even scarcer. Therefore, the matching problem of the initiator has always been a difficult point of LED light curing. Currently, photoinitiators which can be used include TPO, TPO-L, ITX, DETX, BAPO, and the like. However, these initiators do not have a very strong absorption peak in the wavelength bands of 365 nm, 385 nm, 395 nm, and 405 nm, and thus the initiation efficiency is not high. At the same time, compared with the traditional mercury lamp, its power is lower, the irradiation energy is not high, especially the ink-based colored system. If the printing speed is too fast, the ink curing is not complete.

In view of the problems of initiator matching and equipment power, the photocurable resin used for LED curing must have a very high reactivity to avoid problems such as poor curing. At present, there are few UV-LED curing resins available in the market, which are mainly subject to the two problems of reactivity and stability.

Inkjet printing

At present, the market is highly concerned about UV-LED curing technology, with the most innovation in the inkjet field, and the advantages of UV-LED curing just meet the needs of this field.

UV-LED inkjet advantages: energy saving, high efficiency, high resolution, adapt to a variety of substrates. Applications: Industrial or decorative printing, large format inkjet printing, labeling and packaging printing.

Coating printing

Compared with ordinary UV printing, UV-LED coating printing is more energy-saving and environmentally friendly, and has a long service life. It can reduce energy consumption by up to 70-80% and has excellent adaptability to printing materials.

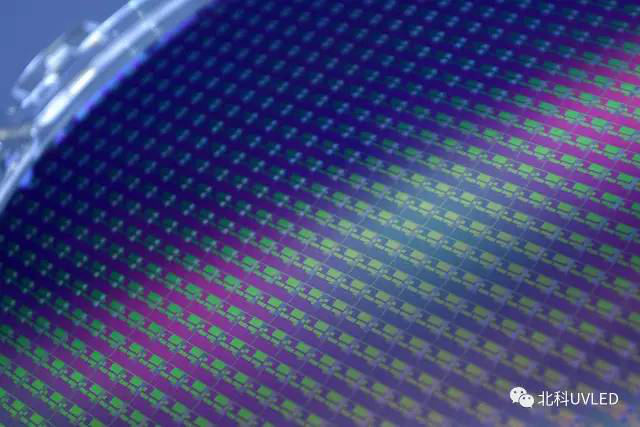

PCB exposure / green oil curing

·Components (capacitors, inductors, various plug-ins, screws, chips, etc.) are fixed.

·Moisture-proof potting and core circuit, chip protection, anti-oxidation coating protection.

·Board type (corner) coating.

·Ground wire, flying wire, coil fixed.

·Wave soldering through hole mask.

Home building

Compared with the traditional coating method, UV-LED does not affect the moisture content of the substrate, and the UV-LED rapid curing construction process is completely realized from the closed bottom, primer, color correction and topcoat, eliminating the tradition. The wood/marble tile bottom, the long drying and curing time of the topcoat and the complicated process of low-solid multi-pass spray construction can realize the full-line mechanization and assembly line operation, which greatly promotes the improvement of the factory capacity.

Microelectronics

There are many advantages to using UV-LED curing glue, such as low heat release, lower energy requirements, saving curing time and position, increasing productivity and making automation easier. Therefore, it is widely used in the field of microelectronics and medical devices to bond, fix and protect.

Manicure field

It is cured by low-power UV-LED lamp. It has low heat release during use and UV nail polish has good curing effect and can keep it bright and new for a long time.

UV coating

LED advantages: cold light source, less pollution, fast curing, low energy consumption, superior film forming performance.

Applications: cell phones, automotive coatings, optical lenses, plastic coatings, fiber coatings.

Optical lens

1. Optical component assembly (lens group, prism, optical engine assembly)

2. Image instrument assembly (microscope, endoscope, infrared, night vision, probe, etc.)

Medical instruments

1. Anesthesia mask

2. syringe

3. Catheter

4. Intravenous infusion tube

5. Vascular implant accessories

6. Hearing aid

7. Detection, monitoring, and imaging equipment

8. Bonding PVC, thermoplastic (polycarbonate and ABS)

Optical Communication

1. Passive components (wavelength division multiplexer WDM, array grating waveguide AWG, optical splitter SPLITTER, optical isolator ISOLATOR, optical coupler COUPLOR, etc.), various glass package structures for bonding or potting, fixing of small components Wait.

2. Active devices (coaxial devices TOSA/ROSA/BOSA, VCSEL, laser collimators, etc.), especially FTTX low-cost miniaturized plastic package structures;

3. Fiber optic cable (overcoat, marking, bonding, fiber optic gyroscope).